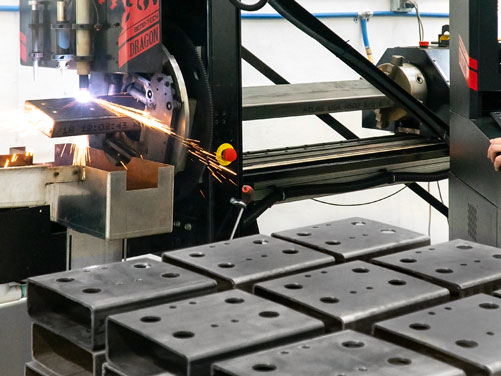

At SCS Manufacturing, we specialize in industrial coating solutions built for performance, longevity, and resistance to extreme working environments. Our coatings protect structural steel, heavy-duty containers, and custom-fabricated industrial equipment from physical, chemical, and environmental damage. Whether you’re dealing with high temperature exposure, corrosive fluids, or frequent abrasion, we help extend the life of your assets.

Our controlled coating facility, located in Nanaimo, BC, supports a wide range of finishes – from decorative enamels to high-performance epoxy coatings and chemical-resistant polyurethanes. Our team uses precise mix ratios, advanced application equipment, and quality-driven processes to deliver protective finishes that stand up to real-world demands.

Commitment to Quality & Certifications

SCS Manufacturing is actively pursuing NACE Certification, demonstrating our ongoing commitment to industry-leading inspection standards and coating compliance. We follow detailed prep, application, and curing procedures that align with your jobsite performance requirements. Our process includes:

-

Product specification reviews and mix ratio validation

-

Surface cleanliness testing and preparation logging

-

Wet film thickness and dry film thickness inspection

-

Final QC documentation with batch traceability (when requested)

We don’t just coat—we verify performance before every unit leaves our paint booth.

INDUSTRIES WE SERVE

Excavator buckets, rakes, and ripper shanks.

Tanks, supports, platforms, and hazardous containment.

Coated beams, bridge hardware, safety barriers.

Sediment tanks, spill trays, concrete washout bins.

UV and salt-resistant finishes for coastal and inland applications.

Structural frames, access platforms, and fleet assets.